5G

UK leads the way in slicing and splicing the 5G network

The United Kingdom seems to have found the answer to clear business cases and value propositions for 5G applications in manufacturing, in its 5G-Encode. Almost 18 months after the project was first announced, and almost a year after the successful completion of phase one, the 5G-Encode project has officially announced the switch-on of the second phase of its industrial private 5G network.

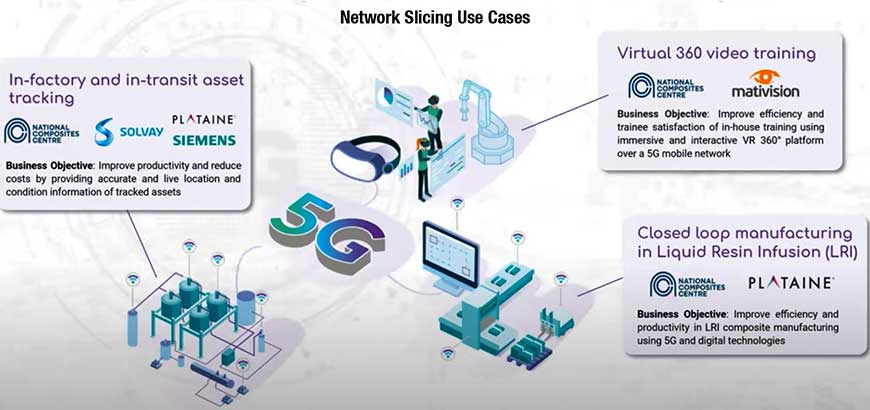

The project shall prove the commercial benefit of 5G technology to enable three specific industrial use-cases – augmented reality (AR) and virtual reality (VR) to support design, manufacturing and training; monitoring and tracking time sensitive assets; and wireless real-time in-process monitoring and analytics.

For the first time in the world, an industrial 5G network can, not only be customized and divided into multiple logical networks, but each of those virtual networks can also be extended across a transport network to reach another virtual network in a completely different administrative domain.

This end-to-end slice delivers continuous connectivity for the seamless delivery of applications across different network domains, regardless of vendor or technology. This would allow, for example, a critical asset to be tracked continuously in real time and with the same quality-of-service as it is transported from the point of production to being received at the destination location.

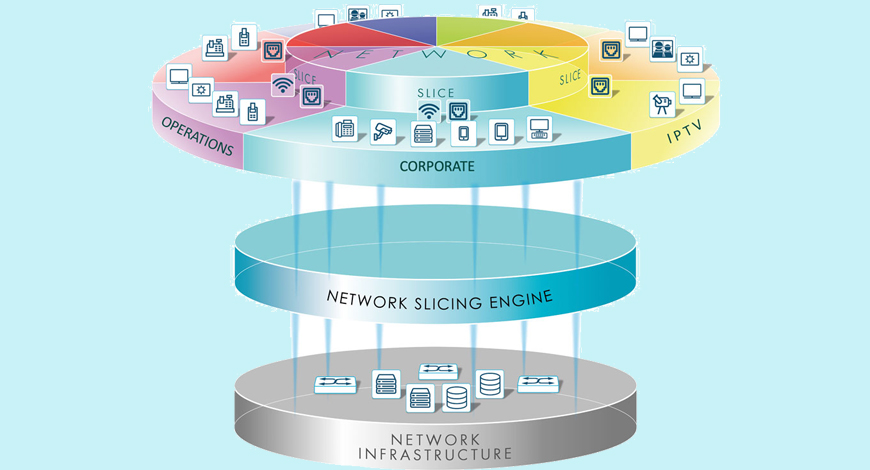

Network slicing is often heralded as one of the real pay-offs for 5G. Through it, 5G operators will be able to engineer the all-important virtual networks capable of meeting various industrial and other high performance requirements over the one network infrastructure.

Within any manufacturing environment, there are multiple tools and machines all requiring different levels of connectivity with varying degrees of latency and throughput, slicing describes the way those virtual networks will be differentiated by the application of qualities like lower latency, rock solid reliability, ultra-low jitter, security and so on. These qualities will be applied selectively to data streams to meet specific application requirements in the industrial environment – every stream being matched with a network treatment to make it fit for its specific task.

The new technologies are defying virtual, logical subnetworks on a common infrastructure and splicing. Splicing is all about taking these slices, and combining them together, the way you want, as bundles of services, or by joining them one after the other in a sequential way, across different domains.

And, the other thing is scalability. The wired solution is the ultimate choice, but the fact is that there cannot be wired solutions all the time, because it always comes back to the stumbling block of scalability.

For instance, if in one center, companies such as Boeing and Airbus come to develop, test, and certify products, and the competitors are working side by side, they are fundamentally working within the same factory.

In effect, they need separate networks, which is what is being developed with network slicing, completely isolating data and connectivity, that cannot interfere. Compare this to a Wi-Fi network. If everyone has that Wi-Fi password, they can actually access the network. But mobile technology is fundamentally more secure.

Service providers will find it possible to comb the domains of the private network with the public network. So, you have basically Telefonica UK, for example, slicing their own network, and delivering a pipe of connectivity across their network. And then, you have enterprises that can slice the network within their LAN environment, and you want those two slices to be joined together, so you can have the continuity of service from a private network to a public one.

Backgrounder. It is a £9 million collaborative pioneering project partially funded by the Department for Digital, Culture, Media, and Sport of the UK government; it is a part of its 5G Testbeds and Trials Program, within DCMS. The project consortium brings together a Tier-I operator (Telefonica), leading industrial players (e.g., Siemens, Toshiba, and Solvey), disruptive technology SMEs covering all aspects of network design, deployment and applications (Zeetta Networks, Mativision, and Plataine), a world-leading 5G network research group (High Performance Networks Group in the University of Bristol), and the NCC representing the high-value manufacturing industry.

The first phase of the network, launched at the National Composites Centre (NCC) last year, used 4G and was meant as a baseline against which results from the private 5G network will be benchmarked.

The first phase focused on testing asset tracking and AR/VR use-cases, with results to be announced at a phase-two launch event at the NCC in November 2021.

For the second phase, 5G-Encode worked with consortium partner Zeetta Networks on introducing network slicing as a key application on the private network.

Specifically, the pair – along with other industry partners – created a new network slice by stitching together slices from one transport network and two separate private networks, one located at NCC HQ and the other at another facility at NCCI located several miles away from the first location.

The effort is based on open standards, and the software is compatible with O-RAN (Open Radio Access Networks) and other open networking technologies, making it both technology and vendor agnostic. This approach supports the UK government’s 5G Supply Chain Diversification Strategy, which advocates deployment models based on open interfaces and interoperable standards for the telecoms industry.

You must be logged in to post a comment Login