Carriers

Supplies chained

2020 saw the global economy juddering to a halt. This year, it got moving again, only to become stuck in one of history’s biggest traffic jams. Exiting the deepest recession in recent history, rising labor costs in China and protectionist trends globally, especially in the United States, have forced a shift in approaches to international commerce, and the COVID-19 pandemic and acceleration of strategic rivalry between the United States and China have made the restructuring of supply chains an urgent task.

In an attempt to devise a careful strategy to rebuild a resilient supply chain, multinationals are addressing challenges and reshoring, near-shoring, and opting for China+1 strategies. However, these are long-term solutions and also not possible for many companies who may have been impacted seriously by the pandemic. Above all, the impact of geopolitical dynamics cannot be ignored.

One company that got caught in this is Huawei. In May 2020, the US Department of Commerce’s Bureau of Industry and Security (BIS) placed Huawei and related companies on the entity list (EL), managed by the BIS under a regulatory framework, including the Export Administration Reform Act, which in principle prohibits the export and re-export of US products (goods, software, and technology) to certain companies.

BIS also announced measures to require BIS’ prior permission for products designed by Huawei and manufactured outside of the United States using US technology and software to not only be exported from the United States but also to be re-exported or transferred to Huawei.

Furthermore, in August 2020, the BIS announced tighter restrictions on Huawei’s access to US-made technology and software and also strengthened its blockade of Huawei’s workarounds to replace its own semiconductor chips with products from foreign semiconductor manufacturers that utilize US products in their supply chains. Then, beginning on September 15, 2020, the United States suspended semiconductor shipments to Huawei.

The US crackdown on Huawei went beyond export bans and called for a test of loyalty for allied countries. In April 2020, the US State Department announced the Clean Path initiative, which promotes the protection of telecommunications infrastructure on five fronts (carriers, apps, app stores, cloud, and cable) from Chinese telecom companies that are believed to have ties to the Chinese government in mind. Clean Path called for communications using the next-generation communications standard (5G) to pass through US diplomatic facilities without any equipment or services from unreliable vendors, such as Huawei and ZTE. In addition, in August 2020, the US government issued new guidelines to protect US communications technology and infrastructure from vendors of concern.

China too responded. At the National People’s Congress in May 2020, Premier Li Keqiang called for a concentrated response to the Six-Points to achieve the Six Moderations necessary to stabilize the domestic economy and protect Chinese society.

“It is understandable why the US has technology sanctions against China, but cutting countries out entirely from advanced technology may cause more harm than good, says Andy Purdy, chief security officer, Huawei Technologies USA. “Before being placed on a blacklist by the Trump administration, Huawei was one of the US chip sector’s biggest customers. It spent around USD 12 billion a year overall in the US, including on semiconductors. The company’s then rotating chairman, Ken Hu, in one of the interviews had said that the company had planned to buy more than USD 20 billion in components from US companies last year, but was prevented from doing so by the export bans.

Revenue from the sale of chips to Huawei has allowed American companies to fund new research that supports US national security goals. When that revenue drops, so does the ability of US companies to invest in R&D. This link is so crucial that when the US government was thinking about expanding the restrictions already placed on Chinese companies, the Defense and Treasury departments objected to the expansion, saying it would hurt US companies’ ability to fund R&D and, most significantly, to support the US defense industrial base.

In addition, the Information Technology Industry Council concluded that an excessive focus on Chinese companies had short-circuited America’s ability to analyze the risks facing its own supply chain. An effective strategy must evaluate all relevant threats to America’s supply chains – not just focus on a single one. Export restrictions that lead to a broad-scale decoupling of Chinese and American technology could also erode innovation. Decoupling America’s tech platforms from China’s was a goal pursued by the Trump administration,” he added.

![]()

The United States sanctions have forced China to increase investments in domestic production of chips and semiconductors. Relying on foreign supply chains makes China vulnerable to any possible boycott in the future. Huawei chip sourcing challenge is a proof for that.

Huawei has been building an independent and controllable silicon industrial capability in the last two years as it attempts to rebuild its supply chain. Investments cover virtually every part of the semiconductor industry, including IC design, electronic design automation (EDA) software, packaging and testing, and materials. Shenzhen Hubble Investment Partnership, a Huawei subsidiary’s investment in Shenzhen Yunyinggu Technology, Qiangyi Semiconductor and Chongqing Xinjing Special Glass bear a testimonial to this. Before the establishment of Hubble Investment in 2019, Huawei had always followed the long-term principle of not investing in any company. Hubble’s mission is closely linked to the production of Huawei chips via wholly owned subsidiary HiSilicon.

Having said that, as of today, “the biggest difficulty for us is the mobile phone business,” says the current Huawei rotating chairman Guo Ping. “As we all know, chips for mobile phones need advanced technology as they are small and have low power consumption. Huawei can design its own chip, but no one can manufacture it for us. Huawei phones have a lot of unique technologies of their own. We are looking forward to the day when the core problem of chip manufacturers will be completely solved in China. The US has created many difficulties for Huawei, but they are solvable. It is in the supply chain where the US has a big impact on Huawei. We need more investment and innovation to deal with the US sanctions,” reiterates Ping.

The pandemic threw the world of logistics into a tailspin, spurring shortages of everything. The system underpinned globalization – production on one side of the planet, connected to consumers on the other by trucks, ships, planes, cranes, and forklifts.

Pekka Lundmark

Pekka Lundmark

CEO

Nokia

“We could have grown faster without supply chain constraints. The main point here is that we are currently not constrained by market demand or our own production capacity. But what is constraining our growth at the moment is availability of components. Component shortages will likely impact 4Q, and limit margin expansion potential in 2022.

And the uncertainty around the global semiconductor market limits our visibility into 4Q and 2022. We are working every single day with our customers and suppliers with two goals: One, to ensure the availability of products, and two, to mitigate the effects of the cost inflation that our industry is currently facing.”

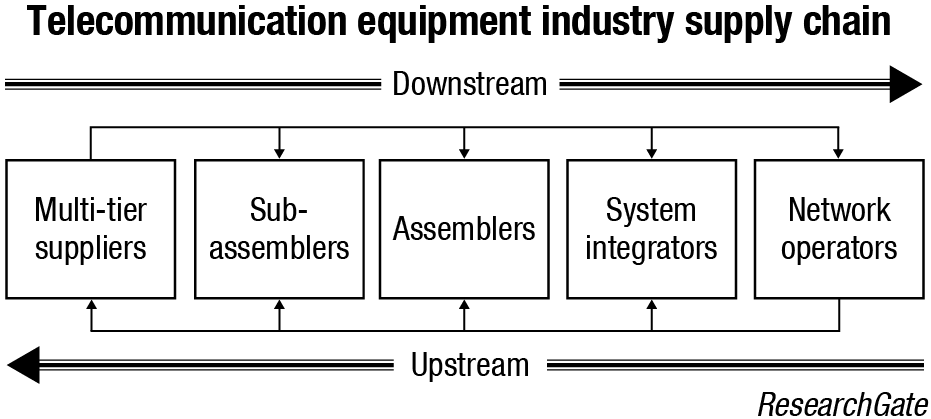

A closer look of how things fared in couple of verticals would be useful.

Semiconductors. The impact of the demand for semiconductors outstripping supply in the global telecoms sector runs far deeper than a few pieces about consumer items, and is not about to end any time soon. Vital communications sector issues, such as IoT and cloud network functionality/services, which are contingent on complex, sophisticated, and interdependent supplier and vendor ecosystems, are being affected too. It is a situation that could well continue into 2023 with the disrupted production of smartphones, routers, and IoT devices having a profound effect on global digitization – and the revenues of network operators and technology suppliers.

Broadband providers have had to make purchase orders up to 15 months in advance, instead of the typical 1–3 months. Vendors are now requiring purchase orders to be placed six months in advance, and expected to increase that timeline to a year in advance. And there is not much anyone can do in the near term to alleviate the situation. The demand between 2020 and 2022 is expected to grow almost 40 percent. This, combined with unprecedented component cost inflation for the telecom industry makes for a bit of a challenging situation.

The increasing lead-time gap indicates that chip buyers are signing up for increased supplies now to make sure they would not be short of semiconductors in coming months. Of course, over-ordering and over-stockpiling adds a further twist to deteriorating situation.

Although semiconductor suppliers are currently investing heavily to increase semiconductor production, capacity remains lagging. Chips are manufactured in giant, expensive fabrication facilities, and constructing new ones takes years. And when we get to 2023 and then 2024, this situation could completely reverse itself, and then there could be excess capacity which would then be reflected on prices.

Shipping. Although the pandemic shuttered factories, shaking supplies of raw materials, one of the main challenges remains freight, and it starts with what used to be cheap, plentiful commodities – shipping containers. About 25 million are in use globally, shuttling goods around the world on some 6000 ships. Companies, such as Denmark’s A.P. Moller-Maersk A/S or China’s Cosco Shipping Holdings Co. own or operate these vessels, with the 10 top companies controlling 85 percent of global capacity.

Container rates and availability are usually built into the annual contracts between the shippers and the carriers, and these deals normally have strict requirements, such as only nonstop service between ports or a minimum of two sailings a week. But little by little, over the past 18 months, customers have had to let those demands go and instead brawl for ship space in the spot market, where the daily rates quoted by carriers and freight agents have soared.

And the rates seemed to change week to week. Two years ago, a 40-foot container cost less than USD 2000 to transport goods from Asia to the US. Today, the service fetches as much as USD 25,000 if an importer pays a premium for on-time delivery, which is a luxury. That is translated into big money for container carriers, with the industry on track to post USD 100 billion in net profit this year, up from about USD 15 billion in 2020. There are companies that just do not have the finances to withstand this, and they have contracted space that they are just not using anymore. They are offering their containers to other companies. At times, the snarls do not end when containers land on a dock. They next need to travel by truck or train to distribution centers. And with COVID-19 embargoes in some places, containers getting stuck in the gridlock, it often pushes the delays back to the ports. Albeit, supply chain professionals and leading technology experts went from office obscurity to holding one of the most important positions at their company almost overnight.

Telcos worldwide have effectively diversified their supply chains. However, some of the current disruption could result in future dips in equipment revenues. While a number of telcos are trying to stockpile inventory to mitigate impact, manufacture and delivery of network equipment will still likely be delayed, slowing network builds.

Excessive demand on mobile and communications networks – including temporary suspension of data caps – could affect service quality, creating a ripple effect as companies across various sectors implement remote-work plans.

Communications providers are dependent on large call center operations to perform critical functions, such as sales and customer service. The majority of retail locations are now shut down, forcing a huge spike in volume through call centers, testing their ability to adjust at scale.

Supply chain reconfiguration will also trigger tax implications.

Ernst & Young, in its newly published report, has identified top 10 risks in telecommunications 2021. From number 1 down to number 10, the top risks listed are: Failure to ensure infrastructure reach and resilience; underestimating changing imperatives in privacy, security and trust; failure to redesign workforce structure and skill sets; failure to mitigate supply chain disruption; poor management of the sustainability agenda; inability to scale internal digitization initiatives; ineffective engagement with external ecosystems; failure to maximize value of infrastructure assets; failure to take advantage of new business models, and inability to adapt to changing regulatory landscape.

In a world of political and economic instability, every industry requires supply chain continuity, security, and reliability. In particular, continuity is essential throughout the entire supply chain, from raw material procurement, production to logistics. Yet it is becoming more challenging to establish supply chains with efficient, end-to-end processes that guarantee material availability, manufacturing productivity, and product delivery.

As supply chain management gets tested, it becomes imperative to build digital, proactive supply chains with continuous, efficient, and secure characteristics. Telecom manufacturers are constantly developing corporate supply chain policies, and deploying strategies, such as production-sales coordination and digital, intelligent operations and providing both its partners and customers with B2C experience in B2B business.

Meanwhile, supply chains are becoming progressively more complex, with growing uncertainties and a huge gap between supply and demand. As raw material supply chain lead times increase and companies form regional clusters, it becomes increasingly difficult for enterprises to quickly deliver goods around the world. The vendors have taken it on themselves to facilitate the information and communications technology (ICT) industry’s supply chain growth by helping suppliers improve their production, onsite management, planning, and end-to-end supply chain management capabilities.

Ensuring supply continuity is key. Before contracts are signed, parties need to discuss configuration alignment, planning, and capability and resource visualization. This ensures contract confidence while reducing supply uncertainty. Vendors need to align their data, processes, and systems with partners, enabling simplified information sharing and end-to-end visualization.

Diverse and inclusive supply chains hold the key. Being more competitive, able to unlock innovation, they provide access to new markets and deliver socioeconomic impact in local operating markets.

Börje Ekholm

Börje Ekholm

President and CEO

Ericsson

“July 2021. Through proactive and continuous measures for supply chain resilience, we have accelerated production to meet customer demand, and we are well prepared for any challenges in the future.

Oct 2021. Some impact was seen from disturbances in the supply chain. Through continuous measures for global supply chain resilience, we avoided customer impact during the first half of the year. However, late in 3Q, we saw some impact on sales from disturbances in the supply chain, and such issues will continue to pose a risk. While we continued to gain share in a growing market, the expected sales reduction in Mainland China, lower variable sales in Managed Services, and some supply-chain disturbances led to a negative organic sales development of −1 percent.”

Telcos are always searching for new, unique, diverse suppliers that would enable enhance their offerings and provide healthy competition for incumbent suppliers.

Casting a wider net enables build a supplier portfolio that includes a broader range of supplier segments. This ultimately allows to increase spend with diverse suppliers, drive higher procurement cost savings, and optimize overall supply chain value.

As we move into 2022, there is optimism for a return to normal in a few months. The widespread supply chain disruptions, plaguing manufacturers and retailers across the world, will probably work themselves out over the next few months, say chief executives of the largest US banks. “This will not be an issue next year at all,” said Jamie Dimon, JPMorgan Chase chief executive, at the Institute of International Finance conference this week. “This is the worst part of it and the great market system will adjust for it.” Still, the chief executives of Bank of America and Wells Fargo acknowledged in remarks at the IIF conference that they initially underestimated the extent to which shortages of labor and materials would upend global supply chains. “Six months ago when this was raised to me by clients around the country . . . you never would have thought it would have gotten so much worse since then,” said Brian Moynihan, Bank of America chief executive, at a recently held conference. Charlie Scharf, Wells Fargo chief executive, expressed similar surprise at the extent of the disruptions, but said he believed the problems were transitory.

You must be logged in to post a comment Login